The Recipe for Great Quality: Supplier Audits & Product Inspections

Consumers want good quality. Consumers pay for high quality. Consumers have come to expect excellent quality. Although most might consider great quality to be what’s placed directly into our consumer’s hands, it should be facilitated and maintained at every stage of your product’s life cycle. From supplier audits to product specifications, production, product inspections and shipping, businesses who choose to insert quality into every aspect of their business may find a more positive customer experience and retention than those who don’t. We’re here to share two aspects of our quality control processes and why customers continue to choose HB International as their Quality Control specialist.

April 12, 2022

![]()

Ingredients for Great Quality: Supplier Audits

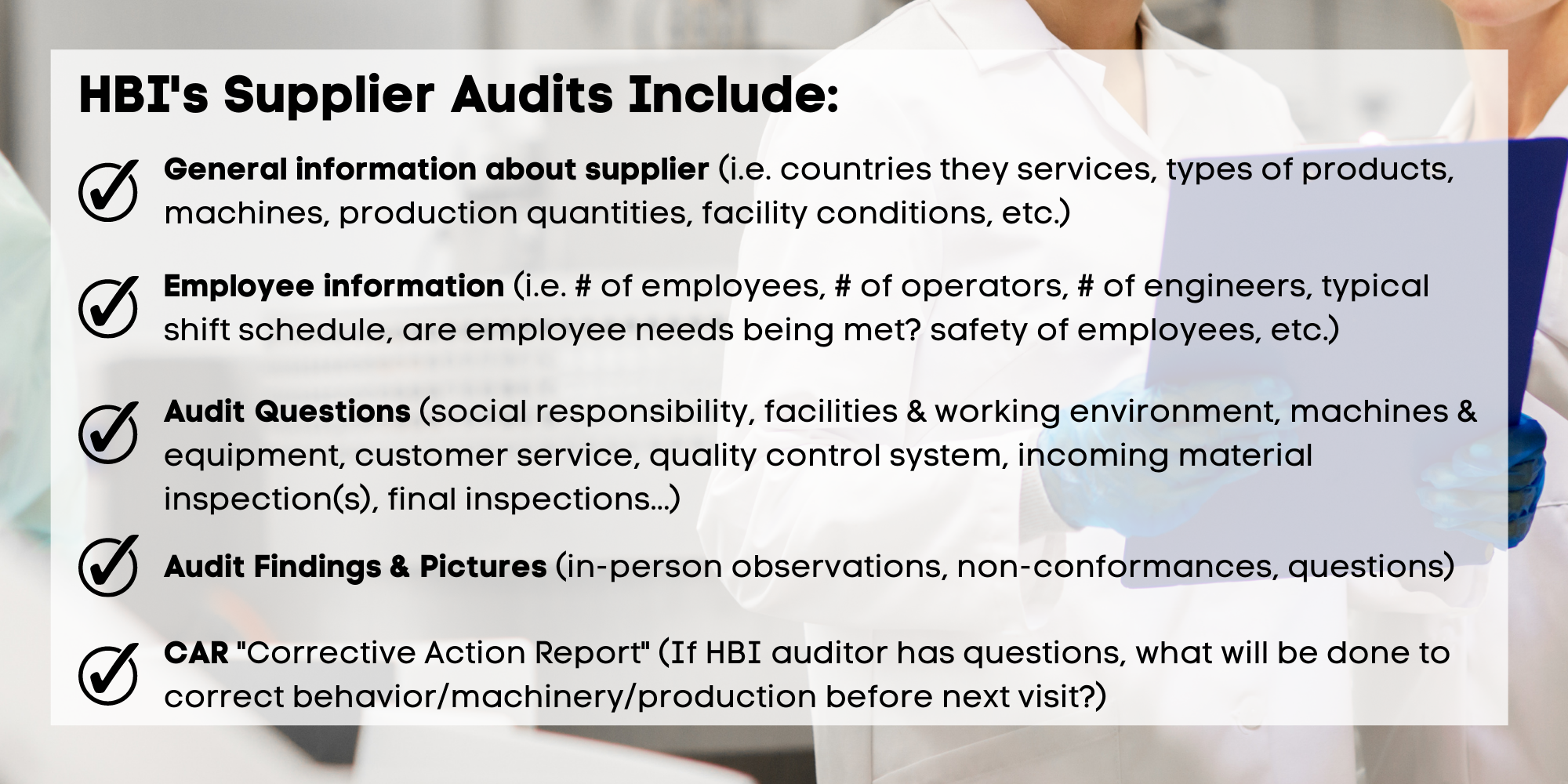

Establishing trust with your supplier is vital to your business’ success. Ensuring that your product is produced with GMP (or Good Manufacturing Practices) should encourage you to know that your supplier follows proper production procedures, implements a good employee management system, and manages healthy working condition protocols. While audits are highly recognized as an excellent opportunity for businesses to vet out potential suppliers, they also offer companies a way to ‘check in’ with current suppliers, make observations, and see that said performance expectations are continuing to be met.

Supplier audits have incredible benefits for both the vendor and the business that chooses to work with them. Not only might an auditor’s results provide information that discloses opportunities to increase performance or reduce potential risks, but audits can initiate positive growth for both parties. From a supplier’s perspective, audits offer the advantage of gaining visibility into areas of potential risk as well as insight to motivate and boost supplier management teams, ensuring all employees remain engaged in their specific tasks and continue to improve their individual performances.

Why Our Customers Appreciate HBI’s Supplier Audits:

Our audits are conducted in person with our certified Quality Assurance team. Certified through BRCGS and FSC 22000, our QA team conducts routine supplier audits to ensure cost, quality, and safety remain a priority. Over the past twenty years, our QA team has developed and evolved HBI’s audits to reflect the many various products that we source. In working with many different suppliers in multiple industries, our team continues to educate and certify ourselves to become experts in these areas for you and your product.

![]()

Ingredients for Great Quality: Product Inspections

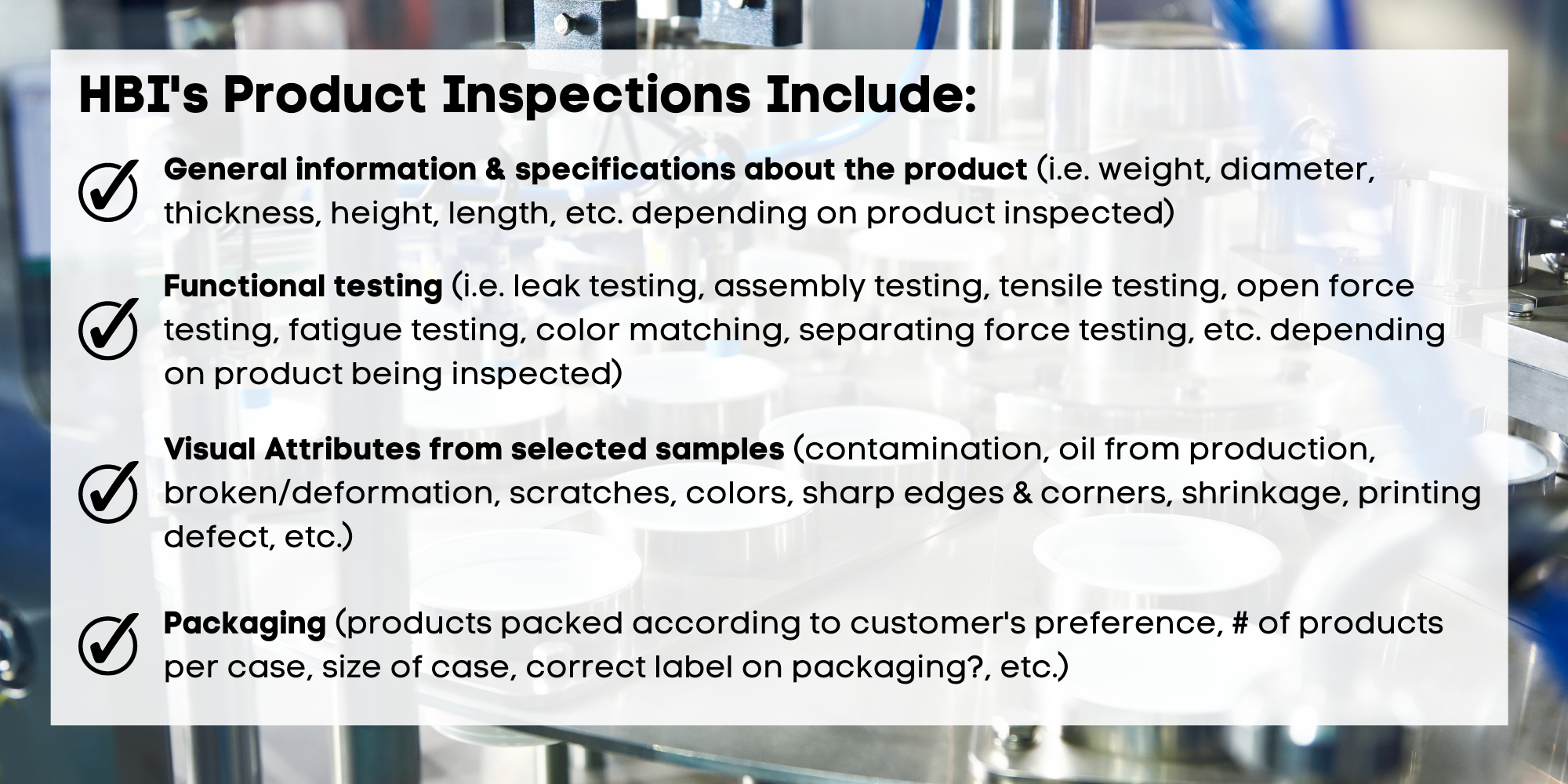

Poor quality is detrimental to any business’ finances and reputation. Product inspections are a chance for businesses to visually see their product, sample their product, and ensure it meets the predetermined quality standards established at the beginning of production. Implementing product inspections has become increasingly popular over time. They are an opportunity to randomly sample your product before it ships and ensure product specifications and packaging accuracy are met. As packaging evolves and industry standards steadily become more regulated, product inspections have also become more robust to meet the gold standard for high quality.

As many businesses are looking to cut costs due to tariffs and increases in raw material and freight costs, for some – the concept of quality inspections is overlooked. While small product inefficiencies may not be noticeable to consumers, there is the concern that these skipped quality inspections may lead to unnecessary costs for businesses. Unfortunately, these missed product inspections could lead to reordering more (unnecessary) products, leading many companies to spend more on product and production costs than they need to. Spending money on good quality products and inspections may lower business costs and save time between production time. The good news? Product inspections can save money on poor quality. The discovery of a faulty product can cease product production, allow for product reconfiguring, and proceed with new specifications and the production of new products, ultimately saving your business the cost of a defective product’s potential recall, unhappy consumers, and reputation.

Why Our Customers Appreciate HBI’s Product Inspections:

Product inspections are a routine procedure for all of HBI’s customers. With our QA team local to our manufacturing facilities, we can conduct in-person product inspections, allowing our team an opportunity to get hands-on with your product before it’s in your consumers’ hands. Our team incorporates the predetermined product specifications to randomly sample your product during production to ensure your product is manufactured to your expectations and ready to be shipped for consumer use. Our priority is to communicate the transparency of your product’s inspection by providing all inspection details and making sure you approve our customer’s inspection results.

![]()

How Can We Help Your Business Continue to Thrive?

As a Global Sourcing Agency, we’re here to cater our services to offer you the very best. We offer an abundance of solutions that provide businesses with exactly what they need to succeed. Whether you’re looking to source a-la-carte or the entire package, our team’s purpose is to offer ways your business can continue to flourish. In having a team that works both domestically and internationally, communication is constant. We are a team of experts, and we want to share our years of international sourcing experience with you. Let us help alleviate the stress of identifying and approving international suppliers and inspecting products when these options are limited due to travel restrictions and costs. In a competitive business world, we have the team your business needs to continue thriving.