Quality Assurance: Seal Integrity Testing Methods

Is your product’s packaging reliable? Are you 100% confident that your product’s packaging is transportable and eliminates any concern for spills or contamination?

January 21, 2021

![]()

Seal integrity test methods are specifically designed to monitor and examine a package’s seal quality in order to increase your product’s shelf life. Leak testing is an essential quality control measure used for many products to assure that any imperfections or defects to the packaging product are monitored and identified before shipping out to consumers. During the various testing procedures, inadequate seals, holes, or cracks are immediately identified and brought to the consumer’s attention.

Quality Assurance team members determine the best testing procedures based on the type of packaging. In assessing the integrity of a product’s packaging, auditors use high-pressure vacuum chambers, neutral pressure situations, as well as water chambers to test a product’s reliability.

![]()

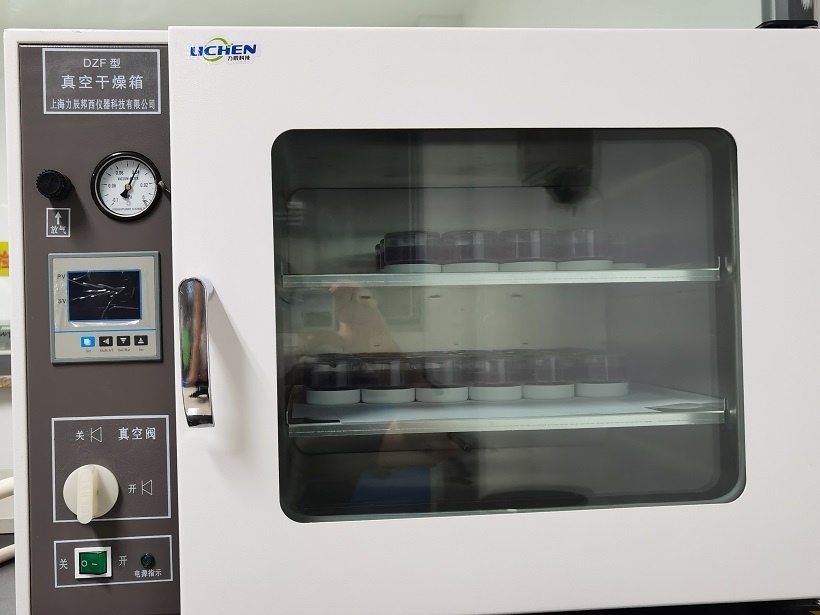

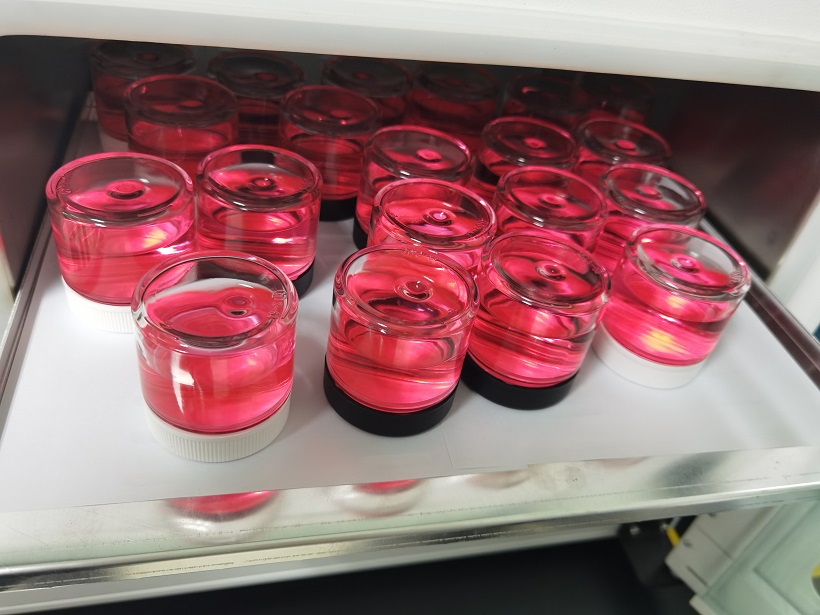

Product Tested with Vacuum Chamber

This standard leak testing method uses a high-pressure vacuum chamber where liquid containers are placed inside the chamber for a predetermined amount of time. During vacuum chamber testing, the tested container is filled three-fourths of the way with a dyed solvent. Caps, sprayers, or pumps are applied to the container, and the packaging is placed upside down or on its side on a piece of white paper. Once the vacuum pressure pump is turned on, the molecules experience a pressure difference. This difference in pressure causes the molecules within the container to expand. As the internal pressure is much higher than the pressure outside of the container, the container will naturally want to expose the liquid to equalize the pressure. Any opportunity for the fluid to escape from the inside will occur during this time, ultimately revealing leaks and inadequate seals.

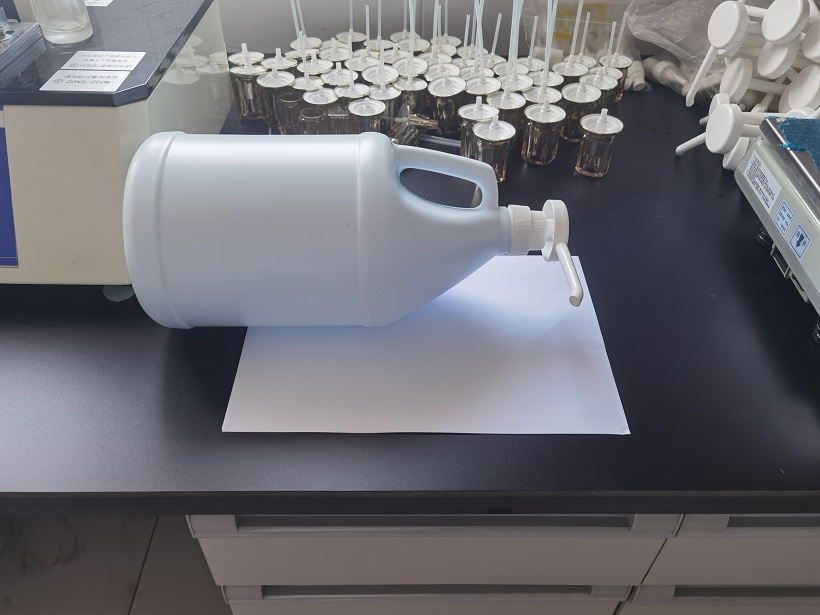

Product Tested with Normal Pressure

Have you ever knocked over a condiment container in your refrigerator and forgot about it? Or, perhaps a shampoo bottle tipped over, and you left it overnight? Another quality test method is a balanced-pressure situation at standard room temperature. Packaging containers are sealed with the specific cap, sprayer, or pump and placed in various positions that would typically encourage the contents within to leak. In this standard pressure procedure, air molecules surrounding the container move at the same speed and pressure as those within the container. For example, when observing a fine mist sprayer and bottle’s seal, the product is filled three-quarters of the way with liquid and placed on its side for a set-duration. The product is placed on a blank piece of paper without any contamination or possible interferences within the area. Typically this test is conducted within a 24-hour window. Again, any opportunity for liquid to escape will occur during this window of time and all leaks and defect seals are immediately addressed.

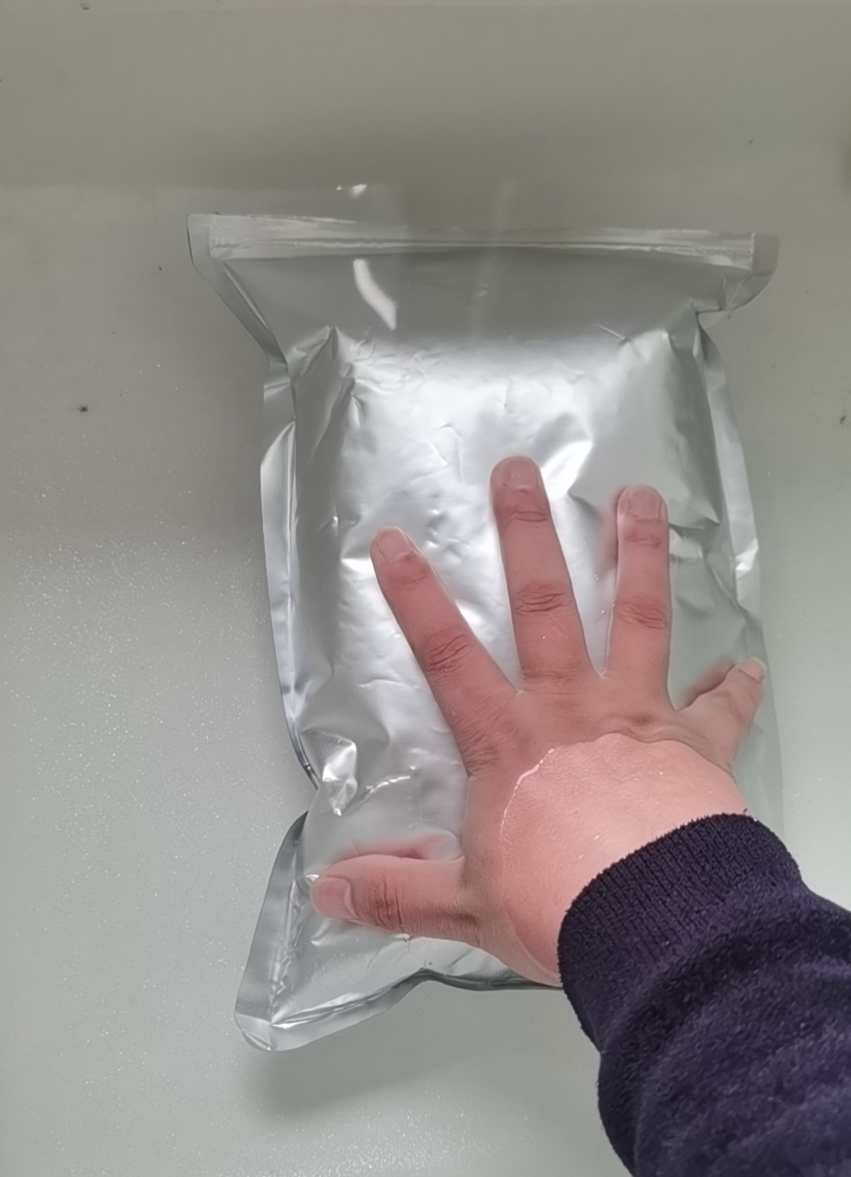

Bubble (Air-leak) Testing

This quality testing method is a procedure that uses bubbles and various pressures to detect leaks or poor seals in a package. For example, a flexible pouch contains air, which is a high pressure. When a flexible pouch containing a high pressure is submerged entirely in a low-pressure water chamber, the air within the pouch tries to neutralize, causing the air within the pouch to escape. If bubbles are visible, this is an immediate indication that a sealing defect or a hole in the pouch has been located. No bubbles? The product’s seal is approved and ready for consumer consumption.

![]()

Why Choose HB International?

We are customer-service focused. Our priority is to ensure you and your customers receive a high-quality product that is consumer-ready. HBI’s Quality Assurance team frequently visits suppliers, completing in-person visits, audits, and in-process and pre-shipment inspections. We continue to communicate with you through these in-person visits to ensure you’re updated on every production step. Suppose a product does not meet HBI’s testing requirements. In that case, it is our responsibility as a team (HBI, supplier, and you) to ensure we understand the specifications of the product and rework the product until the quality issue is dissolved. HBI’s Quality Assurance team is FSSC 22000, ISO 22000, and BRCGS certified.