It’s More Than a Box: Understanding the Basics of Transport Packaging

![]()

The term “packaging” carries a lot more weight than most people think. From glass containers and PET bottles to cardboard boxes and bubble wrap, it’s simple: packaging is any material that is used to protect your goods. Whether the packaging is used as a container for liquids or used to ensure the safety of goods in transit from one place to another, packaging plays a significant role in global supply chains. Consequently, with substantial growth in e-commerce and logistics, transport packaging continues to evolve.

December 22, 2020

![]()

What is Transport Packaging?

Transport packaging is used as protection and containment during the transport of goods. It protects them from potential damage during product transportation, handling, and storage. Transport packaging encompasses industries that are involved in the packaging and shipping of consumer products.

Transport packaging is made up of a variety of materials, including but not limited to pallets, plastic films, boxes, bubble wrap, or molded materials such as glass, paper, or plastic. When it comes down to protecting your goods, different levels of packaging are used before your product “hits the shelves.”

![]()

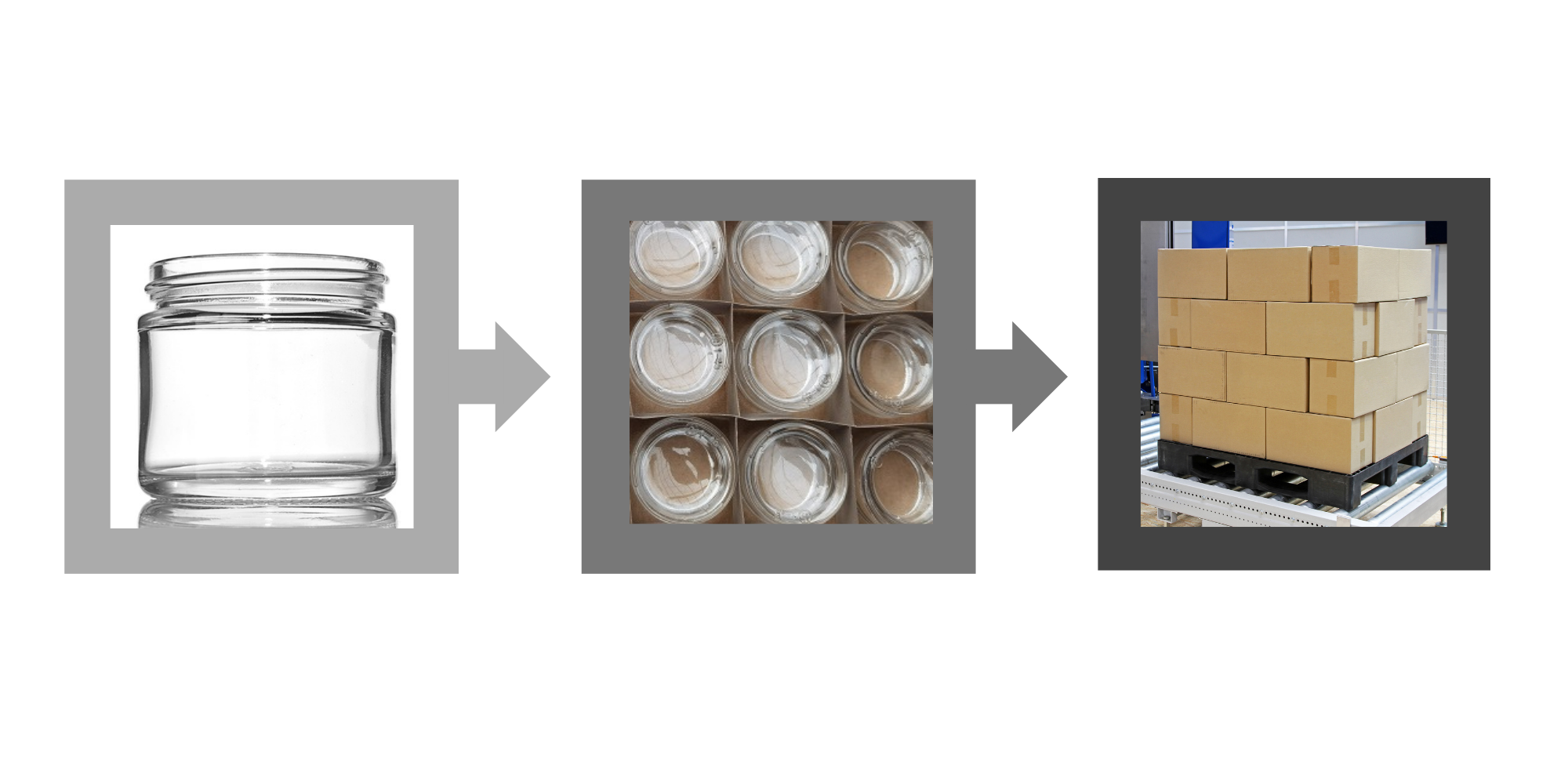

Primary Packaging

Primary packaging is considered the “first line of defense” packaging or “finished product.” Primary packaging is what consumers see on shelves, and it’s what preserves and protects your product from contamination. Also known as the “consumer unit,” this is the first layer of packaging protection and is typically visually appealing, used for marketing purposes.

Secondary Packaging

In this second layer of packaging, primary packages are stored for transportation. Whether you’re a retail shopper placing purchased items in a shopping bag, or shipping glass containers, secondary packaging is used as a way to transport primary packages. Secondary packaging is used to prevent contamination, make transport handling more manageable and more secure, and avoid damage. Examples of this type of packaging are but not limited to single use and reusable shipping boxes and bags, while also including packaging separators called interior dunnage such as airbags, foam wrap, bubble wrap, or paper/plastic separators.

Tertiary Packaging

Entering the third layer of packaging, the primary reason for tertiary packaging is to group the secondary packaging, making the transportation of goods from point A to point B easier. Tertiary packaging contains the products that are shipped and/or handled at outlets and/or distribution centers. Stretch-wrapped pallets containing the secondary packaging (cardboard boxes) allows for easier and safer transportation.

![]()

At the end of the day, the more a product is handled, the risk of damage increases. Packaging plays a significant role in protecting a product as soon as it exits the manufacturing line and enters a consumer’s hands, which is why HBI’s Quality Assurance Team continues to provide pre-shipment inspections with our customers.

![]()

HBI Understands High-Quality Packaging

HBI’s Quality Assurance Team visits with our approved suppliers regularly and conducting audits, and factory/product inspections, including a “Pre-Shipment Inspection.” This inspection is used to manually inspect and ensure that the manufactured product meets HBI and our customer’s quality expectations, closely examining all three layers of packaging to ensure products will arrive safe and secure.

We’re here to make sure your products are retail ready. Let us know how we can help.